In 1966, Deere and Company’s industrial equipment lineup included a pair of small crawlers to which various bulldozer, grader, and loader attachments could be mounted, a line of loader backhoes, and a small elevating scraper. Not a bad selection for a group that had so narrowly defined its niche and was not even 10 years old yet. All of that was about to change, however. In November 1967, Deere’s Industrial Division took the heavy equipment industry by complete surprise when it released the first all-hydraulic, articulated frame-steered motor grader and set the industry on a well-honed cutting edge that is still important today.

Although this machine (dubbed the JD 570 motor grader) was considered small by the industry, it really made a splash because of its innovative steering system. The JD 570 could be steered conventionally with its tilting front wheels, but the frame also articulated in the back of the operator’s station. This feature offered unprecedented maneuverability and made ditch and bank work a breeze since the four rear drive wheels could be placed on the firm ground away from the slopes, while the moldboard and cutting edge could be positioned for optimal production. The value of this truly innovative combined steering system was not lost on other manufacturers and many soon followed with their own designs. Interestingly, Caterpillar would not release an articulated grader for at least six more years.

John Deere historians note that the company’s first foray into the world of road grading and maintaining machinery went back several decades before the JD 570’s release. For example, many John Deere standard tractors were paired with pull-type graders and terracers from makers like Adams, Galion and Caterpillar over the years. In fact, at one point in history, Deere and Co. had teamed with Caterpillar to supply industrialized model “D” tractors to Caterpillar dealers specifically to serve as a prime mover for pull-type graders. Within time, grader attachment makers (like the Hawkeye Manufacturing Co.) bolted their arched front ends and blade carriages to those same model “D” industrials to create more or less self-contained motor patrol style graders and maintainers. The JD 570 was hardly related to any of these projects, however.

Company historians also often point to the JD 570 as a symbol of Deere’s strong commitment to succeeding in the world of yellow steel. Arguably, the JD 570 motor grader smoothed the way for John Deere’s entry into the heavy equipment business and was pivotal to defining the company as something more than a niche player. In a John Deere Spill Sheet published in November 1968, interviews with several contractors and new JD 570 owners yielded comments such as, “As far as we are concerned, the JD 570 is the greatest machine we’ve seen.” Let’s take a look at what made this motor grader so revolutionary—and useful.

For many contractors, the JD 570 was a real time saver simply because it was more maneuverable. For example, the machine’s full-lock turning radius was 18 feet when the frame was fully articulated and the front wheels were fully turned. That’s not too bad for a road grader with just over 17 feet of wheelbase (measured to the center of the rear tandem drive); rather, it was practically miraculous compared with other motor graders of the day. Deere engineers thought ahead when designing that sharp-steering system and created a pedal-actuated differential unlocking mechanism that disconnected the JD 570’s left and right side drive wheels to facilitate the turns. “With the short turning radius and unlocking differential and separate left and right braking, we handle a cul-de-sac in no time,” contractor Tom Harrawood of Ellisville, Missouri said to the Spill Sheet reporter. “Articulation is the big advantage.”

Contractors installing gravel bases for huge bulk oil storage tanks in Lemont, Illinois also pointed to the JD 570’s maneuverability as key to their own success with the bidding process. “We bought the machine just for grading these round bases,” Arbanas Construction Co. Superintendent Walter Johnston said. “It helps us get closer to the center of the base than any other machine you can use.”

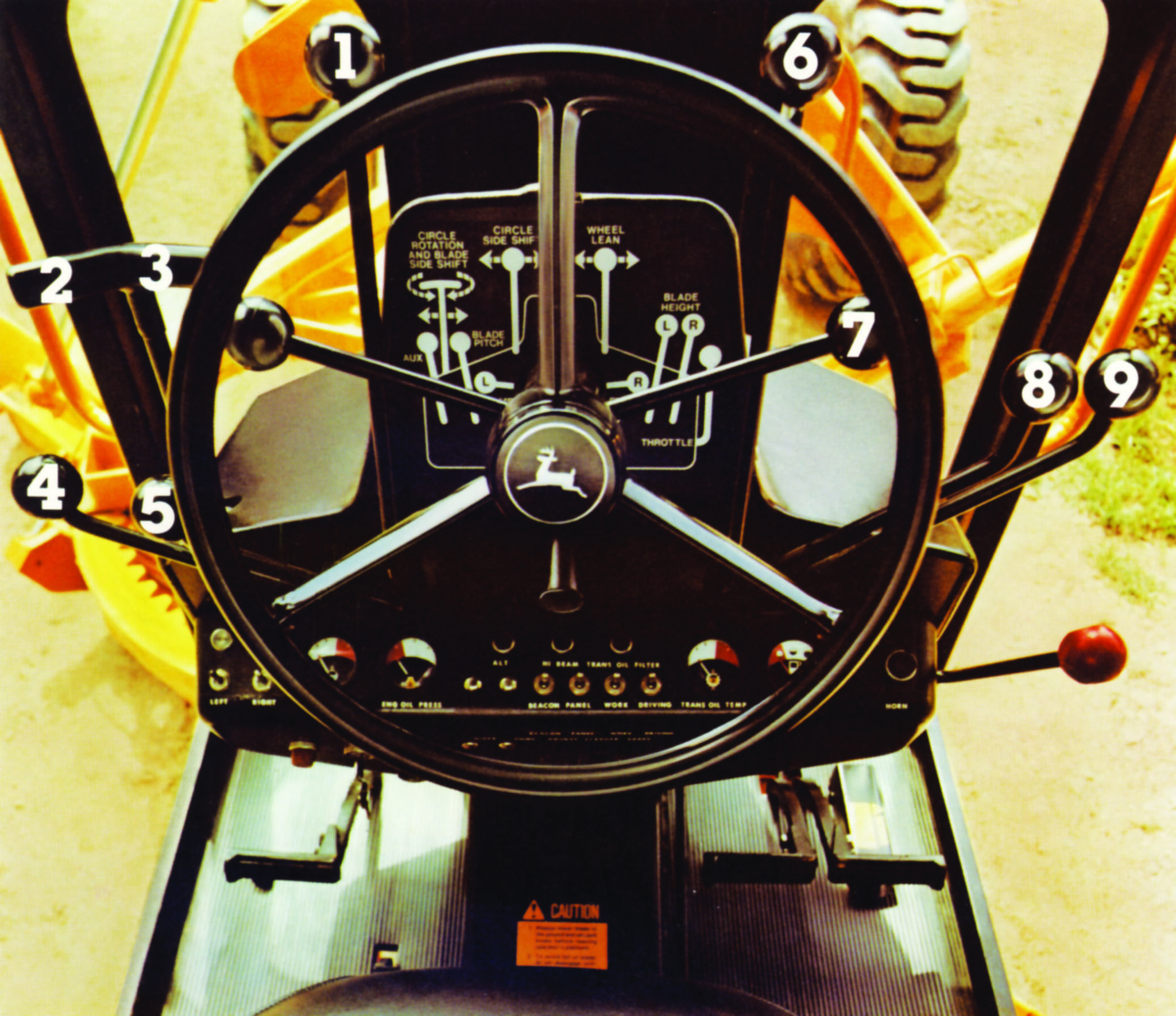

In Kearney County, Nebraska, the JD 570 turned out to be the machine that they wanted and as luck would have it, they got one in early 1968 because the machine came with the lowest bid. “We wanted this motor grader because of the all hydraulic bank cutting capabilities and versatility over others on the market,” County Engineer Rolland Westerbeck explained. Mr. Westerbeck’s grade foreman, Harry Hill, was more pleased by the JD 570’s time-saving operation. “You never have to take your hands off the wheel to bring one end of the blade down—both blade lift levers are on the same side of the steering wheel,” Harry elaborated. “And you never have to stop to shift gears—when you want to go, you just go without clutching.”

Clearly, Deere officials chose happy customers to explain why the JD 570 was so useful; however, the diversity of operators who were found to give testimonials gave the Spill Sheet article some credibility. Whether at work on conventional road grading jobs, spreading fill for 50,000 square feet of warehouse floor, mixing oil and aggregate windrow-style or maintaining a Galveston, Texas beach, the JD 570 received very high marks.

It’s all in the details

The JD 560 had a 12 foot long blade that could be extended to a total of 16 feet with the addition of optional left and right extensions. All of the blade, saddle and circle functions were hydraulically controlled and marketing materials were quick to point out that the design prevented the lever chatter, kickback and knuckle slap that operators of the mechanically controlled blades were well experienced with. Shifting the blade from horizontal to a 90 degree left or right bank was accomplished from the operator’s station and took about a minute to accomplish. This task—if the grader was even capable of making the transitions—often took hours to accomplish with more traditional designs. The JD 570’s heavy-duty hydraulic circle rotated a full 360 degrees and the blade’s pitch was also hydraulically adjustable and could be tipped forward by over 30 degrees.

The JD 570’s blade carriage included a fully hydraulic saddle that offered lever-adjusted angling from 45 degrees left to 45 degrees right of the grader’s mainframe. Additionally, five locking positions offered infinite blade position adjustment from 90 degrees left bank to 90 degrees right bank. That, coupled with the blade carriage’s swiveling A-frame drawbar, allowed greater flexibility and ease in positioning the circle from horizontal to steep bank cuts. In the standard configuration, the JD 570’s blade could also be hydraulically side shifted by 26.75 inches right and 32.25 inches left.

Power for all of that flexibility and maneuverability was provided by Deere’s 303.6 cubic inch displacement vertical inline six cylinder, direct injected diesel engine (3.86 inch bore by 4.33 inch stroke) set up to make 83 maximum engine horsepower at 2,300 RPM. Power was routed from the engine to the grader’s unique (direct connected) power shift transmission with integral differential. This unit offered operators a total of eight speeds forward and four in reverse. A separate hydraulic reverser allowed clutch-less directional changes in the first four speed ranges to make repetitive work much easier on the machine and the operator. A pair of conveniently located levers controlled range and direction shifts independently of one another. Top speed for the JD 570 was listed as “a good 21 miles per hour.”

Power from the integral lever-unlocked differential was routed through a pair of full floating planetary final drives that were located within the left and right axle housings and adjacent to the differential. The outboard ends of the final drives engaged a pair of chain-wheel equipped axle shafts located in the center of the left and right tandem drive unit. Oil bathed roller chains coming off the centrally driven sprocket turned the wheels. In its standard configuration, the JD 570 was equipped with 13.00×24 tires on the driven end. The JD 570’s front axle offered wheel lean left or right of about 20 degrees, steering of up to 51 degrees left or right (not including 22-degree left and right articulation) and oscillation of 15 degrees up or down (30 degrees total) to keep firm footing on uneven ground.

Stopping the nearly 20,000 pound motor grader was accomplished with a pair of foot-operated, hydraulically actuated, power assisted, wet disc type brakes that were effective on all four tandem drive wheels (mounted in the final drive). The left and right side braking was handled separately (a pair of adjacent pedals) to facilitate sharp turns and to provide directional stability in extremely difficult conditions. The machine’s parking brake was an external expanding shoe drum type.

Initially, standard equipment on the JD 570 included running lights (two white sealed beam work lights front and rear, two red sealed beam stop and tail lights rear); hour meter; cigar lighter; horn; air inlet cap; dry type dual element air cleaner; filter indicator; deluxe seat; water temp, transmission temp and engine oil gauges. Options included 10.00×24 tires, manual blade side shift and pitch adjustment, air inlet pre-cleaner, turn signals, fuel gauge, cab, cab heater and defroster, cab windshield wiper (front and rear), floor mat and cold weather starting aids. A scarifier and snow blade attachments were separately available.

By 1970, the JD 570 was listed with the same engine at about 88 maximum horsepower and it was replaced with the updated JD 570A in the early 1970s.

When first released in late 1971, the JD 570A motor grader looked very much like its predecessor, but there were some subtle differences. For example, the JD 570A was equipped with Deere’s 329 cubic inch displacement (4.02 inch bore by 4.33 inch stroke) vertical inline six cylinder diesel engine set to produce about 85 net horsepower. The grader’s drive train was largely unchanged from the earlier version although the machine could now be equipped with larger 15.5×25 tires. The JD 570A’s circle was strengthened and the blade’s lift height increased (compared with its predecessor)—blade side shift was now an even 24 inches left or right. This updated grader could also be equipped with a ROPS compliant cab and the ether starting aid and intake air pre-cleaner were added to the standard equipment. The JD 570A weighed just over 20,000 pounds when fitted out.

By 1974, the JD 570A’s standard equipment list included the ROPS cab with seat belt, turn signals and transistorized voltage regulator in addition to the other items previously mentioned. Since the machine had become popular on many tough construction sites, new options included a heavy duty 12-foot blade, transmission armor (bottom plate), bulldozer, wheel weights and engine side panels. By 1980, the front and rear windshield wipers were also listed as standard. The JD 570A motor grader remained in the lineup with only minor upgrades or options changes until early 1987, after which it was replaced with the updated JD 570B in time for the company’s 150th year anniversary.

The B-series JD 570 was once again very similar in dimensions, weight and capabilities as its predecessor. The JD 570B was powered with Deere’s 90 net horsepower vertical inline six cylinder model 6-359, 359-cubic inch displacement (4.19 inch bore by 4.33 inch stroke) direct injected diesel engine. Power from the engine was fed by direct connection to the eight-speed planetary power shift transmission with hydraulic reverser. This transmission was essentially an updated version of that used in the previous series. The grader was also equipped with several additional critical power train indicators, a 25-degree articulating frame and a long list of optional equipment that included the rear windshield wiper. The JD 570B was discontinued by the mid 1990s and was not replaced.

Closing thoughts

John Deere’s first motor grader set a new standard for chassis and blade control versatility that the industry embraced wholeheartedly. The JD 570 family was accompanied with larger and more robust Deere and Company designs within only a few years of initial release. The JD 570’s larger siblings, the JD 670 and JD 770 motor graders came on the scene within a few years of the 570’s release. By the late 1970s, Deere had also added models JD 772A and JD 672A. These latter two machines were particularly interesting because they were equipped with an innovative (and Deere patented) front wheel drive system that sensed slippage in the rear tandem drive and automatically engaged to help pull the machine through.

By the time the JD 570B was discontinued, it was accompanied with the 670B, 672B, 770B, 772B, 770B-H and 772B-H models. Today, Deere and Co. list six motor graders on its website, including the D-series JD 670, JD 672, JD 770 and JD 772. The details of these machines will be the topic of future stories in this magazine.